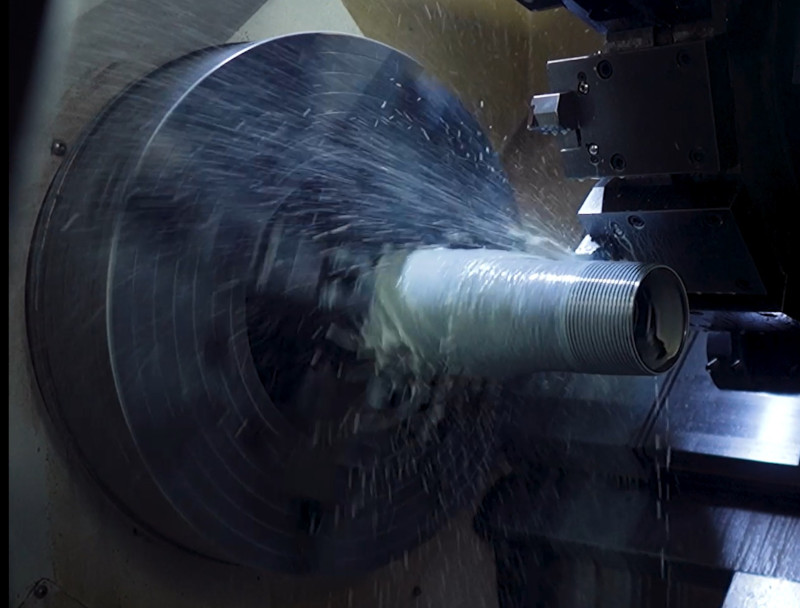

Threading & Premium Connections

Our facility specialises in API threading for casing, tubing, and drill stem applications, ensuring precision and performance in demanding oilfield environments. We offer premium threading services across industry-leading specifications including Vallourec (VAM), Grant Prideco (GP), Hunting, Tenaris Hydril (TSH), and NOV XL, meeting the highest standards for reliability and compatibility. In addition to threading, we provide full machining capabilities and accessory manufacturing tailored to exact project needs, supported by copper plating processes, manganese, and zinc phosphate treatments that enhance corrosion resistance and durability.

- Full-Length Drill Pipe, Casing, and Tubing

- Crossovers, Subs, Side Entries

- Custom Downhole Tools

- Junk Baskets, Mills, Drift Mandrels

- Wash pipes, Lift Nubbins, Lift subs, special complex accessories.

- Customer-designed and API-compliant components

- Casing and Tubing Couplings

- Customer-supplied and OEM Packers

- Customer-supplied and OEM Casing and Tubing Hangers

- Customer-supplied and OEM Float Equipment

- An extensive range of inspection equipment is available to complement our License and customer manufacturing requirements.

Design Review Calculation Process

- Each project is supported by a structured design review and calculation process to ensure compliance, performance, and operational safety:

- Design Input Verification – Review of client specifications, OEM drawings, and applicable API/premium connection standards.

- Engineering Calculations – Wall thickness checks, connection stress analysis, make-up torque calculations, using recognised engineering practices.

- Peer & Supervisor Review – Independent validation of calculations and design assumptions by senior engineers.

- Documentation & Approval – Compilation of design review reports, calculation sheets, and compliance statements for client records.

- Continuous Feedback Loop – Lessons learned from field performance are incorporated into future design and calculation practices.

This integrated process ensures that every threaded or machined product delivered from our facility meets not only dimensional accuracy but also the mechanical integrity and service life expectations required in the oilfield.

Threading Services - Premium & API Connections

At Pioneer Engineering, our facility specialises in API threading for casing, tubing, and drill stem applications, ensuring precision and reliability in even the most demanding oilfield environments.

We offer premium threading services across a wide range of connections from leading, industry-recognised manufacturers, including:

- VALLOUREC (VAM)

- Tenaris Hydril (TSH)

- Grant Prideco (GP)

- Hunting

- NOV XL Systems

Our processes comply fully with API and OEM license requirements to guarantee high performance, reliability, and connection integrity.

Machining & Accessory Services

In addition to threading, we offer accessory manufacturing services tailored to specific project requirements.

Beyond precision threading, we provide a full range of accessory manufacturing and repair services tailored to meet the specific requirements of your project.

Commonly Manufactured & Repaired Components

We manufacture and service a wide variety of components, including:

- Full-Length Drill Pipe, Casing & Tubing

- Crossovers, Subs, Side-Entry Subs

- Custom Downhole Tools

- Junk Baskets, Mills, Drift Mandrels

- Wash Pipes, Guide Shoes, Lift Nubbins

- API-Compliant & Customer-Designed Components

- Casing & Tubing Couplings

- Customer-Supplied or OEM:

- Float Equipment

Surface Treatments & Coatings

All components are treated with specialized surface finishes as required by license specifications. We are fully qualified to apply the following coatings:

- Copper Plating

- Manganese Phosphate Coating

- Zinc Phosphate Coating

- Peen Blasting (Sand blasting)

These treatments enhance corrosion resistance and help prevent galling during make-up and operational service.

Inspection & Compliance

We maintain an extensive range of inspection and testing equipment to fully support both our licensed threading operations and customer-specific manufacturing requirements.

All inspection activities are performed in line with relevant API, OEM, and client specifications, ensuring compliance, traceability, and the highest quality standards across every stage of production.

For a full list of threading licenses, gauges and inspection capabilities, please contact.

Need Something Specific?

Get in touch with our team to discuss your requirements or request a tailored quote today.

We’re ready to support your project with precision-engineered solutions and dependable lead times.

Premium Threading Licenses

| API | Vallourec (VAM) License No. 915 | Tenaris Hydril (TSH) License No. 296 | Hunting Energy Services License |

| Quality & Monogram License | Qualified Connections | Qualified Connections | Qualified Connections |

| ISO 9001:2015 - Reg No. 3094 | VAM TOP | BLUE | SEAL-LOCK BOSS |

| API Q1 - Reg No. Q1-3117 | VAM TOP HT | BLUE LW | SEAL-LOCK HT |

| API 5CT - Reg No. 5CT-1874 | VAM TOP HC | BLUE QUICKSEAL | |

| API 5B - Reg No. 5B-0629 | VAM TOP FE | BLUE NF | |

| API 7-1 - Reg No. 7-1-1355 | VAM TOP KP | BLUE NF | |

| API 7-2 - Reg No. 7-2-1124 | VAM SLIJ II | WEDGE 511 | |

| API 6A - Reg No. 6A-1863 | VAM 21 | WEDGE 513 | |

| API 16A - Reg No. 16A-0486 | VAM 21 HT | WEDGE 521 | |

| DINO VAM | WEDGE 523 | ||

| VAM FJL | WEDGE 561 | ||

| VAM HP | WEDGE 563 | ||

| VAM HP-II | WEDGE 613 | ||

| VAM BOLT | WEDGE 623 | ||

| VAM BOLT II | SLX | ||

| VAM HW | MS | ||

| VAM HW ST | MS XT / XC | ||

| VAM SFC | 3SB | ||

| VAM HTT | 3SB SL | ||

| VAM HTTC | 3SB ST |

| Grant Prideco License No. 17-1629 | NOV XL Systems License No. 2025-003 | Postle Industries License No. 011922DBTB121 | Castolin Eutectic License No. CE 2025-01208 |

| Qualified Connections | Qualified Connections | Qualified Hardbanding Process | Qualified Hardbanding Process |

| XT Series | Xcalibur | DURABAND NC | OTW 13CF |

| HT Series | TUFFBAND NC | ||

| GPDS Series | |||

| VX Series | |||

| DELTA Series |

| Sterling License No. SBP-24/0103-F |

| Qualified Copper Plating Process |

| Brush Method (Approved by VAM and TSH) |