OCTG Management, Inspection and Storage

In accordance with recognized industry standards API RP 5C1/ API SPEC 5CT/API 5A5, Pioneer Erbil offers OCTG (Oil Country Tubular Goods) Pipe Yard Management / Inspection services which encompasses the efficient storage, handling and tracking of tubular products used in the oil and gas industry. It involves goods receipt & return, inventory management, maintenance, inspections, and logistics to ensure pipes are readily available and in optimal condition for immediate use. By effectively managing these aspects it can, in return minimize costs, maximize efficiency, and ensure the safe and reliable delivery of tubulars goods to and from the rig site locations.

Key aspects of OCTG Pipe Yard Management:

Receiving Inspections:

Verifications of Purchase Orders, Delivery Documentation, Mill Certs, Quantity

Inspections performed, Protectors, Markings, Visual tube, Connections, Wall Thickness, Storage Compound

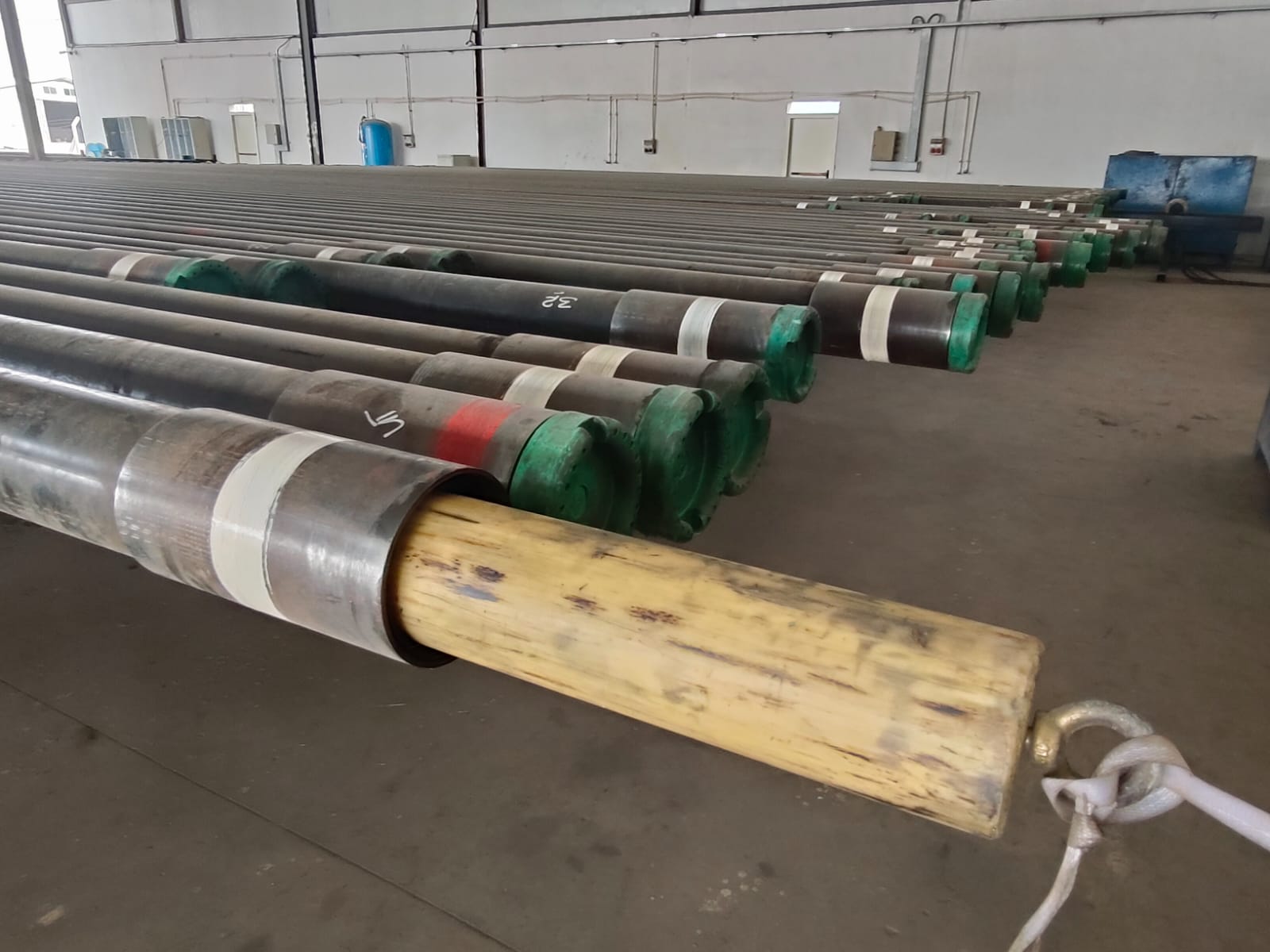

Storage and Handling:

OCTG tubulars require specific storage conditions to prevent damage and degradation, this includes, correct stacking, protection from corrosion, impact, and extreme temperatures.

Correct tubular handling for Corrosion-Resistant Alloy (CRA) materials, specialist non-marking equipment is available and is necessary to maneuver pipes safely without damage.

Regular periodic maintenance and Inspections of tubulars protects from corrosion, degradation and consequent costly repairs.

Pioneer’s large storage areas enable efficient pipe movement, storage, pipe handling, loading and transportation.

Security measures are in place to control access to the yard and prevent unauthorized entry or removal of materials.

Inventory Management:

Maintaining detailed records of pipe serial numbers, heat numbers, and other relevant information ensuring full traceability.

Logistics:

Coordination with equipment owner / logistics company in relation to the transportation, receiving and delivery from the yard to the drilling sites or other locations, loading /unloading and ensuring proper documentation is in place.

Inspection and Maintenance:

Implementing thorough inspection procedures API SPEC 5CT/ API 5A5, Tenaris, VAM, JFE, Hunting, NOV, DS1 both pre & post-delivery / Rig returns ensuring pipes are in optimal condition for use. Rig site Inspections of completion tubulars and drill strings. Utilisation of digital technology, QR and Bar codes to provide traceability from assets to documentation.

Cold storage for Elastomers, Seals and Rubber Products

Controlled temperate storage of perishable parts with traceability and interval checks to ensure longevity and correct treatment to end of shelf lives.